Technology - Textile Quality

Quality Issues

Understanding quality issues is just as essential as understanding standards.

A towel may look perfect on the shelf, but true quality reveals itself only after exposure to water, detergent, heat, friction, and repeated daily use.

This section highlights the most common problems in towels—why they occur, and how thoughtful production can prevent them.

Textile Technology - Quality

Pilling

Pilling refers to the tiny fiber clusters that appear on the surface of a towel over time.

It occurs when weaker fibers break, twist together, and form small balls.

In towels, pilling is typically caused by low-grade cotton, insufficient spinning, or yarn that has not been properly combed.

Towels made with strong fibers and well-spun yarn resist pilling and maintain a smooth, clean surface for much longer.

Textile Technology - Quality

Fiber Shedding

All new towels release a small amount of loose fibers during the first few washes — a normal part of the process.

Excessive shedding, however, occurs when the yarn is poorly twisted, the loops are too open, or the cotton contains too many short fibers.

High-quality towels shed far less because the yarn is tightly spun and the fiber length is more consistent.

Textile Technology - Quality

Color Fading

Color fading is more than a visual issue; it reflects the stability of the dyeing process.

Poor color fastness occurs when low-quality dyes are used or when the towel cannot withstand high-temperature washing.

High-quality towels maintain their color through strong detergents, hotel laundry cycles, and repeated use — because their dyeing process is carefully controlled and properly fixed.

Textile Technology - Quality

Fabric Hardening

A towel that becomes stiff after a few washes is usually reacting to one of three factors: hard water, low-quality cotton, or a dyeing process that leaves excess residue on the fibers.

Well-prepared yarn and clean finishing allow a towel to stay naturally soft — without relying on artificial softeners that disappear after the first wash.

Textile Technology - Quality

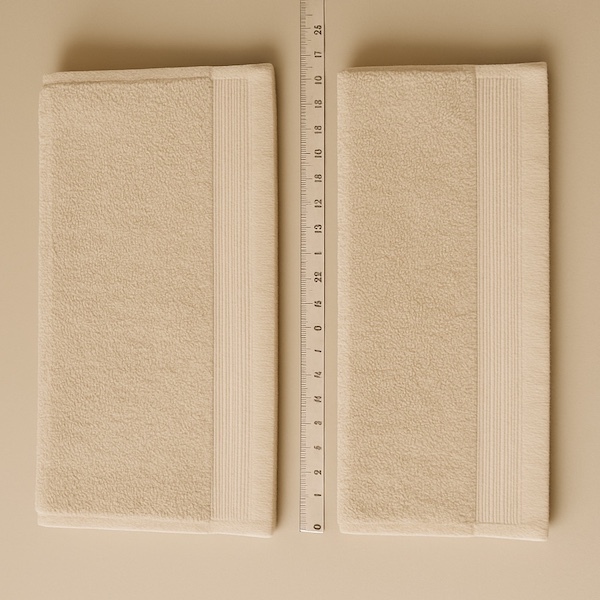

Size Distortion

When a towel becomes twisted, uneven, or wavy at the edges, the cause is usually uneven tension during weaving or weak hemming. Industrial washing can make this issue more noticeable.

A stable construction with balanced tension keeps a towel flat and properly shaped throughout its life.

Textile Technology - Quality

Excessive Shrinkage

Some shrinkage is normal — cotton is a natural fiber.

But excessive or uneven shrinkage indicates that the fabric was not properly stabilized before cutting and sewing.

Towels that undergo proper pre-shrinking and heat-setting maintain their size far more reliably.

Textile Technology - Quality

Terry Loop Integrity

The small loops of a terry towel create its absorbency.

If the loops are too loose, they pull out easily; if they are too tight, the towel feels flat and less absorbent.

Strong loop integrity reflects careful weaving, good yarn quality, and balanced tension — three elements that protect a towel from early wear.

Textile Technology - Quality

Stitching & Hemming Issues

The edges of a towel may look like a minor element, but they carry significant stress during use.

Weak stitching causes hems to open, wave, or separate under repeated washing.

A high-quality towel always maintains clean, tight, and stable hems that stay intact through daily use.

Textile Technology - Quality

Sources & References

These issues are not listed to criticize products — they are part of the textile world everywhere.

The real difference lies in recognizing them and preventing them.

When materials, yarn, weaving, and finishing are handled with care, a towel remains reliable and consistent far beyond the first touch.

Sources & References

• Pilling Test:

What is the ISO standard for pilling and abrasion test?

• Colorfastness Tests:

Guide to Colorfastness Test Methods

• Dimensional Change:

Textiles Test of Dimensional Change Rate During Washing

• AATCC 124:

Dimensional changes of fabrics after home laundering

• AATCC 135:

Dimensional changes of fabrics after repeated laundering

• AATCC 61:

• AATCC 8: