Technology - Testing

Testing Laboratory

Quality is never a guess.

A towel may look beautiful at first sight, but its true performance is revealed only through controlled testing — where numbers, measurements, and standards speak clearly.

This process ensures that every decision, from yarn selection to finishing, is guided by facts rather than impressions.

Textile Technology - Testing

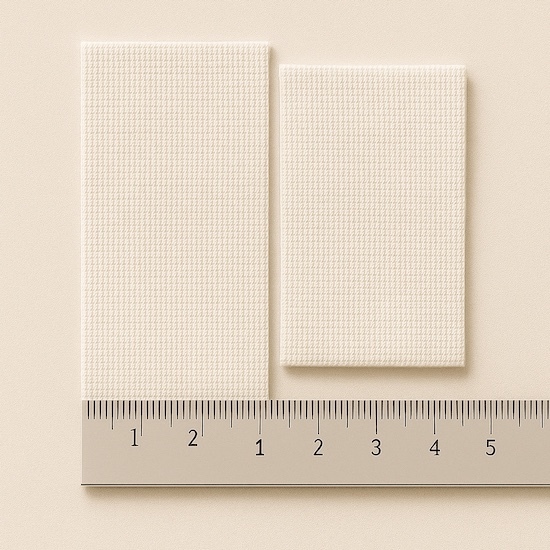

GSM Verification Test

A towel’s GSM defines its weight, density, and overall feel — and even a 5–10 GSM difference can noticeably change its performance.

In the laboratory, a precise circular sample is taken and weighed to confirm that the actual GSM matches the declared value.

Consistent GSM results show that the towel was woven with stable tension and controlled yarn density — the foundation of reliable and repeatable quality.

Textile Technology - Testing

Shrinkage Test

Shrinkage is normal for cotton… but excessive shrinkage is not.

In this test, the towel is washed and dried under standardized conditions, and its dimensions are measured before and after.

This shows whether the fabric was properly stabilized during production and whether it will maintain its size and shape under demanding hotel laundry cycles.

Textile Technology - Testing

Color Fastness Tests

Color fastness is where true dyeing quality is revealed.

In the laboratory, the towel goes through three essential sub-tests:

• Washing Fastness:

To check how well the color holds under heat and detergent.

• Rubbing Fastness:

To measure whether the color transfers to other fabrics or surfaces.

• Chlorine Fastness:

Critical for hotels with pools or spa areas, where towels encounter chlorinated water.

Strong fastness results indicate that the color is stable, durable, and properly bonded to the fiber.

Textile Technology - Testing

Water Absorbency Test

Absorbency is the heart of a towel’s purpose.

In this test, a drop of water is placed on the fabric — or the towel is fully submerged — and the time required for complete absorption is measured.

A high-quality towel absorbs water quickly and deeply, without floating, resisting, or leaving moisture on the surface.

Textile Technology - Testing

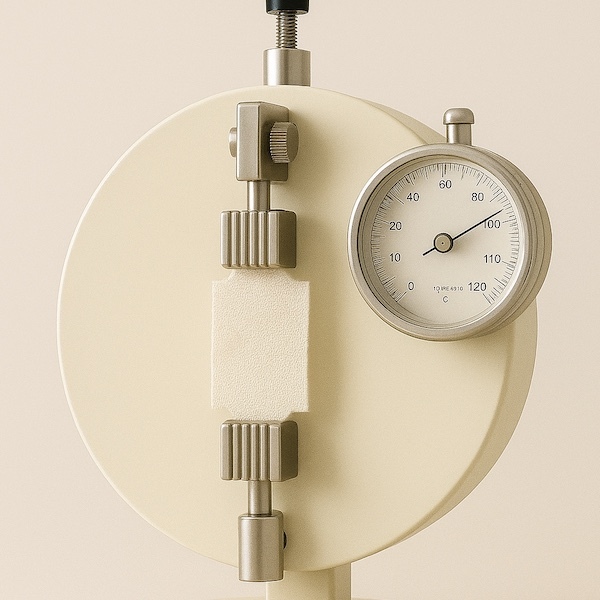

Tensile Strength Test

Towels experience a great deal of repeated stress: pulling, wringing, stretching, and industrial washing.

The tensile test measures how much force the fabric can tolerate before the material fails.

A strong result shows that the yarn, weave, and finishing were all executed with care — and that the towel will withstand real hotel and hospitality cycles, not just the first few weeks.

Textile Technology - Testing

Pilling & Surface Stability Test

This test simulates real-life friction and repeated use to evaluate how stable the towel’s surface remains.

The fabric is rubbed under controlled pressure, and the level of surface disruption is assessed.

A towel with stable fibers and a balanced yarn twist resists pilling and maintains its clean, smooth appearance for much longer.

Textile Technology - Testing

Sources & Reference

Testing does not make a towel better — it simply reveals the real quality behind the material, the weave, and the finishing.

At Heplüks, we rely on these tests not as marketing claims, but as a way to understand every product honestly — so the towels we offer perform exactly as promised.

Sources & References

• ISO 3801:

Determination of mass per unit length and mass per unit area (GSM)

• ISO 6330:

Domestic washing and drying procedures for textile testing

• ISO 5077:

Determination of dimensional change in washing and drying

• ISO 105-C06:

Colour fastness to domestic and commercial laundering

• ISO 105-X12:

• ISO 105-E03:

Colour fastness to chlorinated water

• D5035 - 11:

Tensile properties of fabrics (strip method)

• AATCC 79:

• AATCC 61:

• AATCC 8:

• AATCC 135: